Prepackaged Magnesium Alloy Sacrificial Anode with Backfill

Brand :XIFAN MARINE

Product origin :China

Delivery time :15days

Supply capacity :10000pcs/Month

Prepackaged Magnesium Alloy Sacrificial Anode with Backfill is developed in order to ensure the construction quality of cathodic protection engineering and simplify the construction procedure, making the construction convenient and rapid...

Prepackaged Magnesium Alloy Sacrificial Anode with Backfill

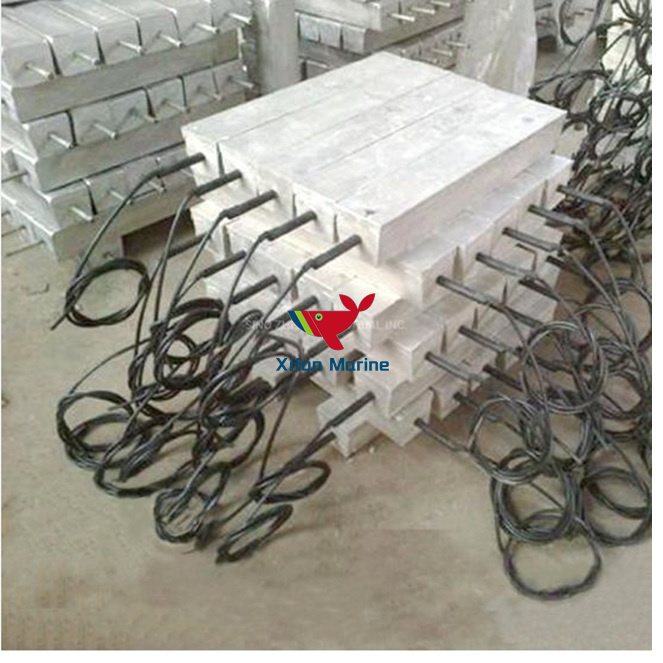

Prepackaged Magnesium Alloy Sacrificial Anode with Backfill is developed in order to ensure the construction quality of cathodic protection engineering and simplify the construction procedure, making the construction convenient and rapid. This prepackaged magnesium alloy anode makes the original operations done in the construction site completed in the factory itself, effectively ensuring the construction and installation quality of anode ground bed.

Assembly Configuration

1. Any type of sacrificial anode;

2. A cable lead: length and size as customer required, welded in sacrificial anode, and according to the proportion of epoxy resin and two butyl ester, using glass fiber cloth or PVC heat shrinkable sleeve for sealing;

3. A bag of special filling;

4. A set of Aluminum welding agent;

5. An anode bag.

Magnesium Alloy Sacrificial Anode

Complete sets of sacrificial anode is composed of one magnesium sacrificial anode, a cable with VV-10mm2 and 3m long, 50 kg filling bag, a cotton bag and a plastic woven bag, that is to say, there is a magnesium sacrificial anode with whose iron core welding a VV-10 mm2 and 3 meters cable in the cotton bag. The welding point is made of insulation treatment and cased with a heat shrinkable tube. 50 kg filling materials are evenly distributed around the magnesium sacrificial anode. The cotton bag is covered by a plastic woven bag.

The Quality Index of the Installation of Magnesium Anode

Cable Connection Resistance: <0.001Ohm

Cable Connection Strength: more than 5 times the weight of the assembled anode.

Chemical Composition

Grade | Alloying Elements | Impurity Elements (no greater than) | |||||||

Al | Zn | Mn | Mg | Fe | Cu | Ni | Si | Ca | |

MGAZ63B | 5.3-6.7 | 2.5-3.5 | 0.15-0.60 | margin | 0.003 | 0.01 | 0.001 | 0.08 | - |

MGAZ31B | 2.5-3.5 | 0.60-1.4 | 0.20-1.0 | margin | 0.003 | 0.01 | 0.001 | 0.08 | 0.04 |

MGM1C | ≤0.01 | - | 0.50-1.3 | margin | 0.01 | 0.01 | 0.001 | 0.05 | - |

MG | ≤0.02 | ≤0.03 | ≤0.01 | ≥99.9% | 0.005 | 0.004 | 0.001 | 0.01 | - |

Electrochemical Performance

Grade | Open Circuit Potential | Closed Circuit Potential | Actual Capacitance | Current Efficiency |

-V,Cu/CuSO4 | -V,Cu/CuSO4 | -(A*h/kg) | % | |

MGAZ63B | 1.57-1.67 | 1.52-1.57 | ≥1210 | ≥55 |

MGAZ31B | 1.57-1.67 | 1.47-1.57 | ≥1210 | ≥55 |

MGM1C | 1.77-1.82 | 1.64-1.69 | ≥1100 | ≥50 |

Standard Specification for Magnesium Anode

Size | Specification | Weight (kg) |

Length*(upper bottom+lower bottom)*Height | ||

MG-22 | 700×(130+150)×125 | 22.00 |

MG-14 | 700×(120+100)×102 | 14.00 |

MG-11 | 700×(110+90)×88 | 11.00 |

MG-8 | 700×(95+75)×75 | 8.00 |

MG-4 | 350×(95+75)×75 | 4.00 |

MG-2 | 350×(55+60)×55 | 2.00 |

Note: size can also be produced according to customer’s requirements | ||

Xifan marine offer a variety sizes &shapes of Aluminum Anodes for option,OEM service also accepted,just send us your drawing and logo.If you

are interested,pls feel free to contact our sales team for further discuss.